SLEEVESTAR

SLEEVESTAR

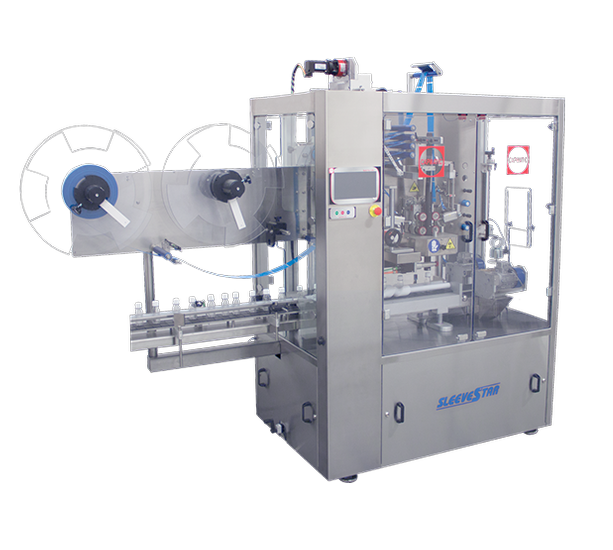

A complete automatic system is used to apply a shrinkable body band around the bottle at a speed of up to 300 bottles per minute, depending on the components.

APPLICATOR:

- A bottle will be indexed one at a time in sleeving distribution station by a twin stepper motor-driven feed screw electronically synchronized with the feeding station.

- Motorized support for the second sleeve reel inside the machine

- Double support for the second sleeve reel placed outside the machine

- Mechanically supported mandrel

- "ServoHeart" multi-blade cutting device

- Mechanically/pneumatic sleeve centering device.

- Sleeve orientation device

- Sleeve dragging geared by brushless motors

- Sleeve throwing geared by brushless motors

- Sleeve positioning device

- products expeller with pneumatic or soft device

OPTIONAL STANDALONE DUAL MOTORIZED BAND UNWINDER:

- Complete with self-standing independent frame base

- Complete with self-standing independent frame base

- Anodized aluminum structure base

- Adjustable Stabilizer foot

- Lexan door

- Low-level sensor to engage band unwinder when necessary

- Series of alleviating web tension system

- Reel motorization

- End roll of film detection

- Film change accumulator with a capacity of 30 M (100') to change the reel without stopping the machine

millimeterLABELSTAR STEAM SMART TUNNEL ™ 4 HEADS

- Frame wholly clad in stainless steel AISI 304

- Stand-alone, adjustable cells with millimetric reference at 360°

- Replacing nozzles steam injection

- Double electronic control for temperature managing

- Visualization of entering/exiting pressure

- Valve for security managing

- Over-heating steam valve

- Doors with accident-prevention glass

- Steam separator SpIrAX Sarco

- Condensation recovering device SpIrAX Sarco

- Proportional valve SpIrAX Sarco

- Aspiration/positioning gauge with a millimetre scale

- Conveyor tape

- Collect drops tray

- Steam aspirator geared by Omron/Danfoss inverter

- Internal lighting

- Electrical switchboard in stainless steel AISI 304

- Accident prevention protections under CE regulations

- Accident prevention protections under PED regulations

- Steam Consumption 150Kg/H

- Air consumption 30 l/min.

- Install power 24Kw

- Dimensions 2500 X 800 X H 2000 (100 X 31 X h 80)

| Category | Labeling Systems |

|---|---|

| Application | Underlap | Body (excluding the cap) | Haft body | Cap seal | Full Body (including the cap) | Body with Vertical perforation |

| Speed* | Up to 300 BPM** |

*Speed and performance criteria are subject to testing with actual samples.

**BPM = Bottle(s) Per Minute